The Shunding rubber plant was officially put into operation in July 2010, becoming the first private rubber processing enterprise with an actual production capacity of 80000 tons per year. The product sales layout covers more than ten countries in China, Europe, Southeast Asia, and Africa.

The production uses butadiene as raw material and adopts nickel based catalyst production process technology, incorporating new processes, technologies, formulas, and equipment continuously improved and perfected by major domestic enterprises over the years. The technological level, product quality, comprehensive energy consumption and other indicators of the device have all reached the first-class level in China.

It is generally used in combination with other types of rubber to manufacture various components such as tire tread, sidewall, and carcass. Under harsh driving conditions, it can significantly improve the wear resistance of tires and increase their service life. It is also used in the manufacturing of tapes, hoses, rubber shoes, and other industrial products with high requirements for cold resistance and wear resistance.

Our company's Shunding rubber products have long-term cooperation with Sinopec, which can fully ensure the stable sales of products and the long-term stable operation of equipment. At the same time of production, a large number of technical talents have been cultivated, possessing certain technological advantages.

| Item | Specification | Typical value | |

|---|---|---|---|

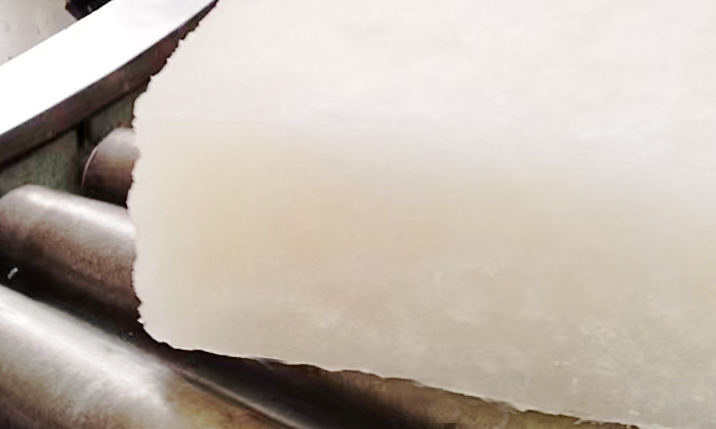

Appearance | Light-colored and semi-transparent, initial shape is blocky, free from coking particles, mechanical impurities, and oil stains. | Light-colored and semi-transparent, initial shape is blocky, free from coking particles, mechanical impurities, and oil stains. | |

| Volatile mater/% | ≤ 0.50 | 0.3 | |

| Ash Content/% | ≤ 0.20 | 0.2 | |

Raw Rubber Mooney Viscosity/ML(1+4)100℃ | 45±4 | 45 | |

| Mixed Rubber Mooney Viscosity/ML(1+4)100C | ≤ 65 | 60 | |

| Tensile modulus/MPa | 25min | 7.0~12.0 | 9.3 |

| 35min | 8.0~13.0 | 10.2 | |

| 50min | 8.0~13.0 | 10.5 | |

| Tensile Strength/35min/MPa | ≥13.2 | 15 | |

| Elongation /35min /% | ≥330 | 400 | |